By Michael Boroson, CTO

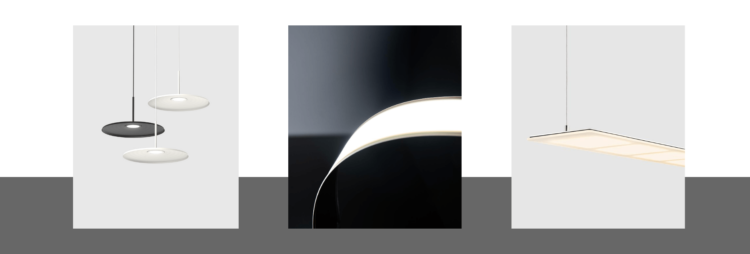

OLED technology is everywhere. OLED displays are in people’s pockets as the screens on cell phones. They are on walls as eye-popping televisions. And they are showing up in automobiles, embedded in windshields and dashboards. Meanwhile, OLED lights are illuminating offices and hotels. They are serving as taillights in new Audi models. And they are changing the relationship between lighting and healthcare.

Let’s look at the differences and similarities between OLED light technology and OLED display to understand why one is used for certain applications over the other.

What are the similarities between OLED display and OLED lighting?

Both devices are based on the same solid-state physics principles. Simply put, OLED technology is comprised of organic semiconductor materials that emit light when electrically energized. The OLED materials emit all wavelengths of interest directly and do not need a phosphor conversion to achieve the desired spectrum.

OLED’s unique light quality serves both applications superbly. For lighting, the naturally diffuse output positions OLED fixtures as the glare-free, full color experience that is highly desired for visual comfort. For display, the direct color emission allows for a high color gamut including true black.

Both applications embrace the ultrathin, even flexible, device profile and lightweight integration. These attributes facilitate design concepts that are not realized with any other technology.

What are the major differences between OLED display and OLED lighting?

The differences between OLED as a light engine and as a display are driven by their respective applications. Displays transmit images, videos, and messaging – usually at very high image data rates (>120Hz). Lights provide functional illumination, ambiance, and, at times, communicate as indicators.

As a functional light source, OLEDs operate as a uniform, high brightness, white spectrum, large area surface light engine. The lifetime demand for lighting is very long, usually exceeding 10 years. OLED lights meet these demands extremely well. Displays, in comparison, are usually a fraction of the brightness and operate as red, green, blue (RGB) individually addressed pixels which have lower demand on lifetime.

It is useful to think of OLED light panels as “one big pixel” or a series of “large segments” while displays have very small pixels. Light segments are 1000x larger than RGB display pixels. To give you a reference, that is like the difference between the length of Central Park in NYC, and the distance from NYC to LA!

In order to show high resolution video, display pixels are refreshed at data rates usually greater than 120Hz. This requires an expensive TFT (thin film transistor) substrate to control the pixels. Lights, on the other hand, can have addressable large segments that dim or change at a much lower rate and do not require the expense of TFTs.

A summary of the differences between OLED display and lighting is provided below.

| Passive Matrix Display | Active Matrix Display | OLED Lighting | |

| Applications | Sub-display/MP3 | Mobile phone display/TV | Any Lighting |

| Substrate | Glass/ITO pixelated | LTPSilicon TFT | Glass/ITO large area |

| Emission | R,G,B saturated | R,G,B saturated | All, especially white |

| Brightness (cd/m2) | 400 | 400 | 8,500 |

| “Pixel” Size | ~0.005cm x 0.01cm | ~0.005cm x 0.01cm | 12cm x 12cm or larger |

| Defect Tolerance | Up to 2 pixels | Up to 2 pixels | 0 |

| Value Enabler | OLED/Driver IC | TFT backplane | OLED |

| Market Development | Declining | Strong Growth | Developing |

| Problem Areas | Limited Size | TFT yield/stability | Cost in market |

How reliable is OLED lighting?

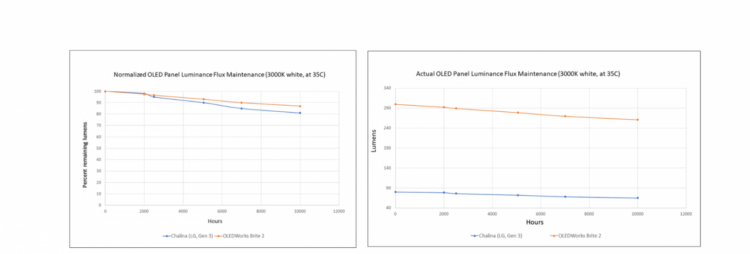

For solid-state lighting, lights don’t fail completely like with fluorescent or incandescent lighting. Instead, their lifetime is considered over when they can only produce 70% of their total brightness. OLED lighting can maintain 70% lumen output, for over ten years or more, even at high brightness. This is particularly impressive since lighting can be 20x brighter than a display, and lifetime is inversely related to brightness.

The ruggedness and reliability of OLED lighting is further demonstrated by the implementation of OLED in automotive taillights. The automotive industry has incredibly rigorous standards for the ability of lighting to function in extreme conditions such as high heat, high humidity, and severe cold. Meeting the environmental challenges of vehicle applications speaks volumes for OLED reliability.

When to use display, when to use light?

Although OLED displays and OLED lights use the same fundamental technology, OLED displays are, of course, not meant to be used for lighting, nor are they optimized for the requirements of illuminating spaces or tasks. Although someone could use an OLED display as a light source in an emergency, nobody would hang up displays to light their spaces due to light intensity, lifetime and cost.

OLED lights, unlike OLED displays, are optimized for illumination, so OLED lights are much brighter than OLED displays (8,000 nits for OLED lights compared to less than 1,000 nits for OLED displays). OLED lights also have much longer lifetimes than OLED displays.

As mentioned earlier, OLED lights have longer lifetimes. OLED lighting drops to 70% initial brightness with over 100,000 hours of continuous use compared to OLED displays that drop to 50% brightness over the same time period, from a much lower starting brightness.

Finally, OLED lights are designed and manufactured to be low cost, with the OLED lighting panels priced more like a light bulb than like the high-end pricing of an OLED display. By contrast, OLED display’s capability for high image data rates makes it ideal for showing images, videos, and messaging via phone screens and televisions.