![How Supplier Relationships Differ When Working with OLED Lighting [Video Interview]](https://www.oledworks.com/wp-content/uploads/2022/06/ISAL-Interview-Header-Partnerships-750x254.png)

By the OLED UX Team

What is Commercial Readiness?

Commercial readiness is the foundation for trust in a product, technology and supplier. Commercial readiness means that the product delivers customer value. Commercial readiness means reliability: from product, to delivery, to customer service. Commercial readiness means the only surprises are when the experience exceeds all expectations.

Expectations in the automotive industry are a particularly high bar. What does it take for a technology to be commercially ready in this industry? Is OLED ready?

Customer Value

“You press the button, we do the rest” – George Eastman, Kodak Camera

In 1887, George Eastman introduced a camera that transformed the complex, bulky, and expensive photography experience into a facile, lightweight, affordable, every-man snapshot experience. This revolutionized the industry and user behavior. Just look at images from before the film camera and see the stoic looks of the once-in-a-lifetime professional pose. These are in great contrast to the playful photos that subsequently emerged, capturing life and telling stories.

130 years later, George’s mantra conveys the essential for delivering customer value. The keys to product value are: to realize customer’s vision; enable simplicity; and build quality into every customer interface while providing affordable solutions. This holds true for members of the automotive community.

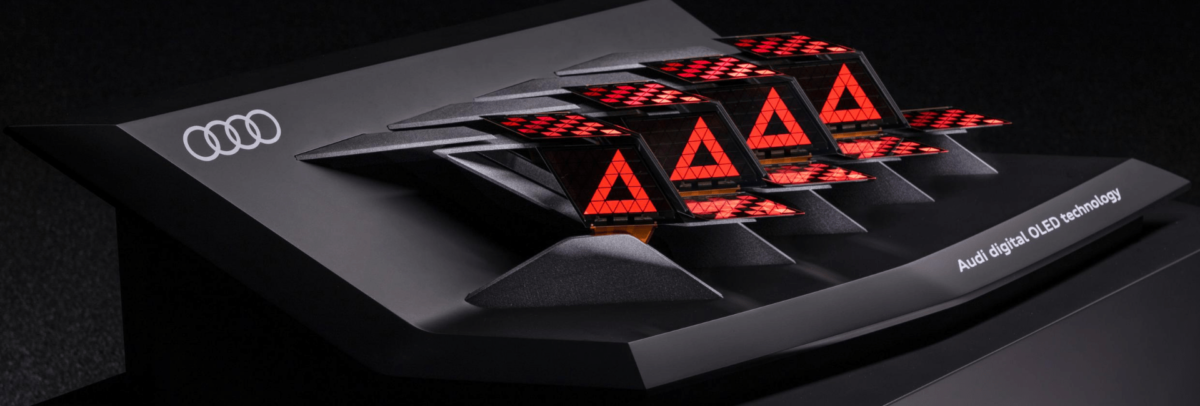

OLED hits the mark. Audi, BMW and Mercedes are pioneering the use of OLED in tail lights. Audi’s Stephan Berlitz, Head of Lighting Innovation, expresses how the combination of light uniformity, integrated segmentation, and reduction of component count simplifies tail light integration and supports a vision of custom design and communication through light. And these attributes are uniquely OLED, not achievable with any other lighting technology.

Performance and Reliability

With safety and environmental sustainability as priorities, the automotive industry is highly regulated with very demanding reliability and performance standards. Technology development follows similar milestones to those defined for many government projects, with proof of concept and validation testing from the component level to system integration.

Throughout the technology readiness process, environmental testing is performed to ensure the technology performs in stressful environments. Tests include:

- high temperature and humidity (85C/85%RH)

- very low temperatures (ex. -40°C)

- rugged terrain to see how it handles shock and vibration to the system.

Testing is validation that the product works. To ensure the product is reliable for the life of the system, technology readiness also requires implementation of quality systems from supplier to manufacturing process to design tolerances. This means the manufacturer must understand the critical and interactive aspects of the technology including:

- materials

- design elements

- manufacturing equipment capabilities

- interfaces or constraints when integrated into the customers final configuration.

The degree of expertise the manufacturer brings to the table is essential for collaboration with the customer. The manufacturer can transform the customer vision to a technology solution; and the customer can be confident in deploying the technology product in the demands of the automotive industry.

OLED has been through the rigors of automotive testing. The marriage of OLED simplicity with proven reliability has been demonstrated as shared by Audi’s Dr. Kruppa.

Customer Experience

Product excellence isn’t the only thing that manufacturers need to keep in mind. Every touchpoint with the automotive customer must have the same rigor as the product. The customer must be confident that production can meet volume and delivery schedules. Likely, the client plans to expand the product platform into different car models and needs evidence that the manufacturer is positioned for rapid uptake and increased volumes: without compromise in quality.

The devil is in the details. Manufacturers must have disciplined processes in place for determining if a product is commercially ready for market.

- Are packing and shipping requirements in place, protecting the product during transportation while enabling shipment quickly and affordably?

- Are all automotive-specific quality systems in place?

- Are all training protocols verified and executed?

- Is documentation under controlled release?

- Is part tracking in place and verified?

- Is customer service knowledgeable and ready to reflect product and corporate excellence through customer service?

Customer value is not limited to technology or product simplification. It encompasses a collaborative and seamless relationship with the customer.

Affordability with Scale

So, you have a reliable product, control of quality and suppliers, excellence in customer support. Now we must look at the final commercial readiness benchmark: affordability.

It is rare that a new technology enables new capabilities at prices equal to or less than the technology being displaced. The biggest cost driver is low (introductory) volumes. However, technology maturity, i.e, yield and production efficiencies as well as initial capital investment, impacts costs for new product technologies.

The manufacturer must understand how to turn the knobs of scale, supply, and engineering excellence to lower costs in support of the customer’s vision: All with no compromise on quality.

If a manufacturer can achieve these benchmark metrics, they are commercially ready. OLED lighting for the automotive industry has gone through rigorous testing and can offer customers a superior light quality with a price point that continues to decrease with further market proliferation. A product that offers superior performance and reliability.

Commercial readiness, in 21st century lingo, means “no worries”.

![The Exciting Future of Automotive OLED Technology – What’s Next? [Video Interview]](https://www.oledworks.com/wp-content/uploads/2022/07/ISAL-Interview-Future-Header-750x254.webp)

![[On-Demand Webinar] Why OLED for Automotive Lighting: The OEM and Tier 1 Supplier Perspectives](https://www.oledworks.com/wp-content/uploads/2022/03/MicrosoftTeams-image-15-750x254.png)